23.4: Donation identification numbers (DIN)

23.4.1: General structure

The donation identification number (‘donation number’) – ICCBBA Data Structure 001, plays a critical role in the safety of the blood supply. It provides a unique identification number which cross-references blood components and samples taken at the time of donation.

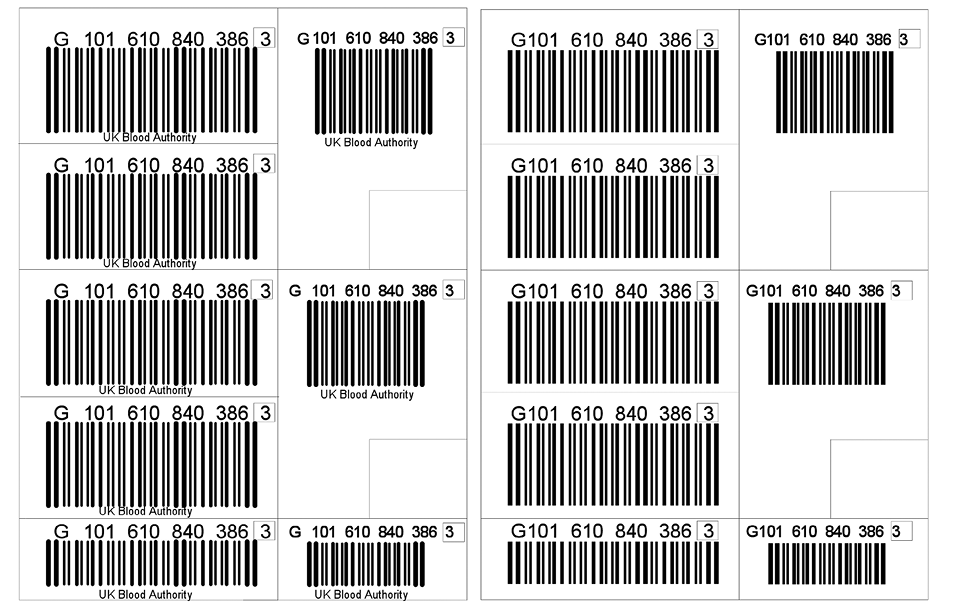

An example set of identification numbers is shown in Figure 23.3. Barcode density information is provided in the ICCBBA ISBT 128 Standard Technical Specification. The structure of the donation identification number is described further below. The example shows labels of various sizes and densities due to their use. If required, a tag can be incorporated in the labels designed for the blood tubes to facilitate the placing on the tube straight by users. This alignment is critical for blood samples being tested in analysers where the barcodes are read ‘in situ’ by internal barcode readers.

The donation identification number contains the facility code from where the donation has originated. These codes can be viewed on the ICCBBA website.

Blood Establishments can optionally add text below each number in the set to show from which Blood Establishment the donation originated.

Figure 23.3 ISBT 128 donation number sets (with and without Blood Establishment text)

23.4.1.1: General

All labels should have tamper evidence designed into the numbers sets to reduce the chance of a label being removed and re-stuck, i.e. any tampering with a label should deface the label making it unusable.

Labels should be self-adhesive using a non-invasive biocompatible adhesive (see ISO 10993 series – expanded in Chapter 26).

23.4.1.2: Requirements for pre-printed labels

Donation identification number (DIN) labels must be generated in primary sets under strictly controlled conditions which ensure that all the labels in a set bear the same number, and that each set is unique. It is the responsibility of the manufacturer of the label sets to undertake appropriate quality control measures to ensure these conditions are met.

The required number of individual labels comprising a set, the configuration of the labels and the commencing number for the print run, must be defined by the ordering authority at the time of order.

Quality control of sequential print must be organised to obviate the possibility of duplication within a print run, and also to avoid the misplacement of the various cutting devices which would cause any set to contain two different numbers.

Any unusable numbers or missing numbers must not be replaced.

Any roll/pad containing an incomplete sequence for any reason must have the discrepancy marked at the beginning of the roll/pad, or the manufacturer must supply a separate list of missing numbers. The total permissible missing numbers must not exceed 1% of the quantity ordered. Each roll/pad should not contain more than six missing numbers per 200 sets.

Pre-printed barcodes on number sets should be of decodability level no less than B to reduce label mis-reads.

The layout of the eye-readable numbers should follow the 4,3,3,3,1 format (see Figure 23.4).

Labels printed should have the correct facility identification code.

No barcodes within the number sets should have a height of less than 6 mm.

A quiet zone of at least 2 mm either side of each barcode is included in the label design.

Any incorporated check digits must be correct. This includes both barcode-incorporated and eye-readable check digits included in the design.

All adhesives used in production of these labels must be non-invasive biocompatible (see ISO 10993 series – expanded in Chapter 26).

Label colour: The labels must be printed black on a white background. Where required by the ordering establishment, part of an order may incorporate a coloured stripe (usually to assist in the identification of new (first-time) donors or sample-only donations). A colour must be selected which will not interfere with the efficiency of any barcode reader in decoding essential information.

23.4.1.3: Requirements for demand-printed labels

Additional donation identification labels may be demand-printed at the point of use.

Where demand-printing is used to generate additional labels for an existing set, the label must only be generated in direct response to the electronic input of a number from the original set.

Where demand-printing is used to generate new label sets, there must be controls to prevent number duplication.

Where ICCBBA flag characters are adopted within ICCBBA Data Structure 001, they must be used in accordance with the standard, and if they are incorporated within final component donation numbers, they must have been authorised by JPAC on advice from SACIT.

Locally printed barcodes should be of decodability grade level not less than C to reduce label mis-reads (see ISO 15416:2001).

The layout of the DIN eye-readable numbers printed should follow the 4,3,3,3,1 format (see Figure 23.4 and section 23.4.2).

Where applicable, labels printed should have the correct facility identification code.

No barcodes should be created with a height of less than 6 mm.

A quiet zone of at least 2 mm either side of each barcode is included in the label design.

Any incorporated check digits must be correct. This includes both barcode-incorporated and eye-readable check digits included in the design.

23.4.2: ISBT 128 donation identification number (DIN) barcode and text

Labels will follow the ISBT 128 Specification for Data Structure 001 with the exception of the eye-readable presentation.

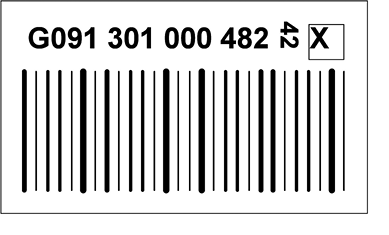

The eye-readable presentation of the donation identification number must be presented in 4,3,3,3,1 format with the check character boxed (see Figure 23.4).

It is strongly recommended that all characters are of equal size and weight. The font used should be selected to clearly distinguish between similar alpha/numerics (e.g. 0 and O, 1 and I), and should be as large as possible within the constraints of label size.

Where keyboard entry of donation number is used, the full number and check character should be entered, and application software should verify the string format and check character value. Use of pre-programmed ‘hot keys’ is not an acceptable alternative.

Calculation of checksums and the corresponding check characters for the ISBT 128 numbers is described in the ICCBBA Technical Specification.

Note: Currently the UK standard only incorporates the modulus 37,2 check digits. If future developments include the flag characters in the donation number, they must be placed on the label at 90 degrees to the eye-readable text between the six-digit unit serial number and the eye-readable check digit. When the checksum is replaced with flag characters the eye-readable check digit must always be included in the label format. Any use of flag characters must be authorised through JPAC on advice from SACIT (see Figure 23.4, right).

Figure 23.4 Labels showing the use of flag characters. On the left, the label shows the eye-readable format 4,3,3,3,1 layout with the check digit in a box, and on the right, the same label shows the use of the flag character